Latest News

Photos of our old factory near Cardiff

I was tidying an old industrial metal wardrobe in our engineering room when I came upon a file labeled 'photos'. It was a treasure trove of images taken between the 30's and 70's, and even included one of the factory being built on the then new Treforest trading estate, near Cardiff. Looks like they were just finishing off the road :

We had two of these factories side-by-side, that went back a long way with the offices in the front. One factory housed our circular knitting plant and making-up division, as we produced our own fabric and made garments in those days. The other building contained our warp knitting, creels and engineering division. It was in this building that we made propeller parts for the war effort.

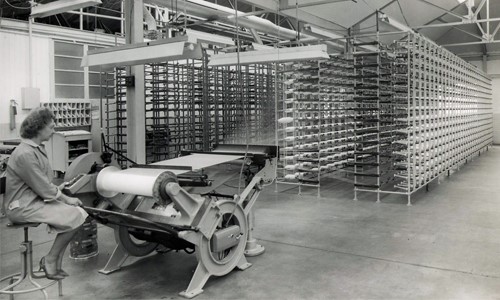

The photo stash was mainly concerned with creeling, which is where a 'beam' of yarn is prepared, ready to be put onto the warp knitting machine to be knitted into fabric.

These images are from the 30's or 40's, where the ladies operating the 'warpers' were watching carefully for broken threads. Once the beam was full, it would be transferred to the knitting machines behind them.

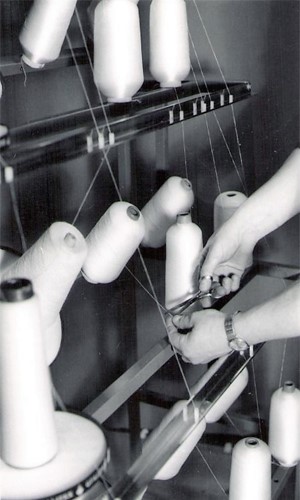

Repairing a broken thread:

In the 60's the factory was re-equipped with new faster warping machines. The creels (the framework that held the bobbins) were made by us, and designed by my Grandfather Harold Stanier.

One of my first jobs in the factory was running one of these machines (that's not me in the image). The weight of the beam could be colossal, and if you saw a yarn missing in the yarn sheet you'd press the lever as fast as you could, which would put on the brakes to arrest the momentum.

It could be that a bobbin had run out, or the thread had got snagged and broke. Mostly we were using nylon when I ran the machines, and unlike natural fibres, this attracted static so the fibres forever wanted to stick to each other and tie themselves in knots. To help rapidly detect broken yarns, my grandfather developed a number of yarn-break detection devices, such as the black stop-motions below :

He also created the units in front of each bobbin that were there to add tension to the yarn, and keep them under greater control. Cunningly, granddad added break detectors to these too, so broken threads were detected automatically.

Today New House still make these units. They've changed quite a lot, but granddad would still recognize them!

© 2025 New House Textiles TRADE